In Walden’s first guest blog of 2021, BlueConduit, a pioneer in the use technology to help communities identify lead service lines, outlines what predictive modeling is and how they use it help their clients.

Replacing lead service lines (LSLs) is a public health and infrastructure priority that can be a costly and time-consuming endeavor for municipalities. Predictive modeling allows for faster, more accurate identification of LSLs.

The American Water Works Association (AWWA) estimates replacement costs could be as high as $30 billion. Uncertainty around the number and location of LSLs make it difficult to execute efficient replacement programs. Predictive modeling has been proven to have significant positive impacts in the identification, inventory, and replacement of LSLs, reducing the time and cost to replace them.

Conventional Methods vs. Predictive Modeling

The processes that water systems use to budget and prioritize their replacement projects carry significant public health and utility costs, and they are often using incomplete, inaccurate, and unreliable historical records to make these decisions.

BlueConduit, a water data analytics company that helps cities reduce uncertainty around LSL inventory and location, has seen this firsthand. One city the team worked with had initially estimated that 10-20% of its pipes contained lead. However, a statistical analysis that included a representative set of inspections estimated that roughly 37% of active water accounts contained lead. After 25,000 inspections, the true proportion of lead in the community was 38%. This accuracy allowed the city to request the appropriate funding to remediate the problem and target the homes most likely to have lead lines. The same data challenges due to misleading or outdated records are shared by many municipalities and water utilities.

How It Works

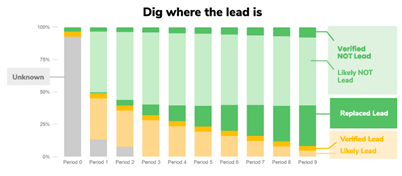

Predictive modeling uses information that is known (e.g., location, year built, water main size and material, construction records, etc.) to make an initial prediction about something that is not known with certainty – in this case, service line material. The utility gathers data on service line material at a representative set of homes. Combining that data with the previously known information, the model assigns a material likelihood (that is, a probability of lead between 0-100%) to parcels with “unknown” service line materials. As those unknown materials become verified, the predictive model incorporates this new information and updates the likelihoods. These parcel-level likelihoods help municipalities “dig where the lead is,” saving time and money all while eliminating negative environmental health impact.

The Association of State Drinking Water Administrators (ASDWA) has published two documents related to predictive modeling. The first, coauthored with BlueConduit, is a white paper on the principles for using predictive modeling in service line inventory.

Key Benefits of Predictive Modeling

The accuracy of this model drives three primary benefits. First, a municipality saves time by avoiding unneeded excavations. Second, the time saved when addressing the “unknowns” in the above example could generate more than 25% in financial savings.

Finally, the quick identification of those parcels most likely to have an LSL enables municipalities to proactively engage in community outreach and adopt a program to reduce potential lead exposure before any excavation begins.

About BlueConduit

BlueConduit is the leader in using predictive modeling, working with more than 50-communities, for lead service line identification and materials inventory. Beyond being the pioneers in this field, we have demonstrated success in multiple water systems and continue to innovate in ways that increase accuracy and efficiency for our customers. Our commitment to transparency in our methodology fosters trust and collaboration with customers and stakeholders.

For additional information, please contact us at: Info@BlueConduit.com, https://www.blueconduit.com/