Semi-Annual Reporting, Lab Management, and Permitting

Semi-Annual Reporting, Lab Management, and Permitting

Walden was contracted to provide engineering and environmental services to a manufacturing client that produces heavy-duty signs, tags, markers, and other items for industries like construction and utilities.

Because this client operates in New York City (NYC), they need to submit semi-annual reports to the NYC Department of Environmental Protection (NYCDEP) from a lab that is certified by the NYS Department of Health (DOH) under their Environmental Laboratory Approval Program (ELAP) program. They are also subject to federal regulations due to the use of metal in their operation.

Four locations are regularly tested for materials like Cadmium, Chromium, Copper, Lead, Nickel, Silver, Zinc, and Cyanide, plus Mercury and Molybdenum from the two housetrap locations. Additionally, four grab samples per day for four days were taken at the End-of-Process Point and tested for Toluene and Xylene.

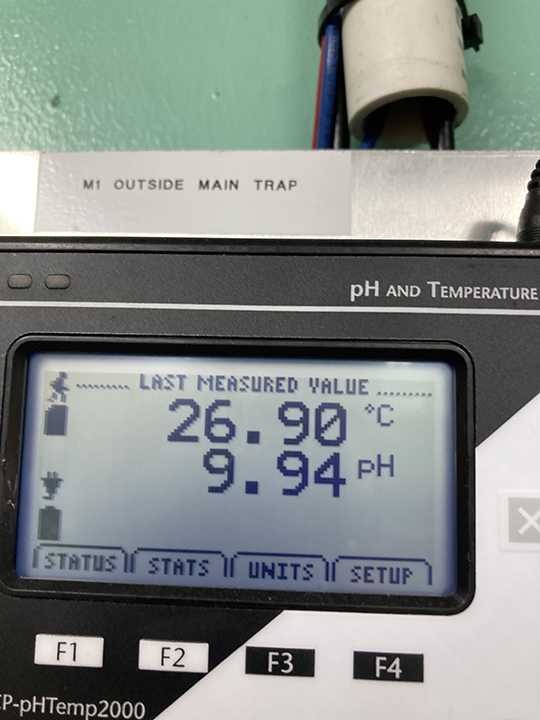

Walden was required to prepare summary reports for the client including recording the Chain of Custody of samples, monthly pH readings, total discharge flow for each day of sampling, hazardous waste manifest, and a copy of their Toxic Organics Management Plan (TOMP), which were also submitted to NYCDEP.

Although this client must have a permit to discharge industrial wastewater into the local sewerage system, they also must have an air permit because they have industrial processes that create exhaust which results in air conditions that could be hazardous. All sampling at this facility is done in accordance with 40 CFR 403.12, which governs where samples should be taken to test for specific compounds. For example, grab samples must be used to test for pH, cyanide, oil and grease, and volatile organic compounds (VOCs). While composite samples must be obtained for other pollutants adhering to specific details of where and how the samples must be obtained.

Walden’s scope of work also includes inspecting treatment systems to ensure they are in good working order, which may include maintaining and calibrating their current pH monitoring system for NYCDEP-designated location housetraps and End of Process points. Data from calibration activities is downloaded and reviewed by Walden staff. After an inspection, the monitoring system data logs are stored and then cleared. The system is then restarted. All NYCDEP Air Permit emission locations and equipment are inspected for proper operation and to ensure the equipment is always in good working order.

Semi-Annual Reporting, Lab Management, and Permitting

Semi-Annual Reporting, Lab Management, and Permitting