OSHA Safety Standard on Heat Stress

During summer time, it is usual for every person working outdoors to be concerned about hot working conditions that might lead to heat stress related illnesses/injuries. According to the Occupational Safety and Health Administration (OSHA), every year, dozens of workers die and thousands more become ill while working in extreme heat or humid conditions. OSHA does not have a specific standard that sets requirements for employers to comply with in order to prevent/recognize/treat heat related hazards. However under the General Duty Clause (Section 5(a)(1) of the Occupational Safety and Health Act), employers must provide a working environment “…free from recognizable hazards that are causing or likely to cause death or serious harm to employees.”, including heat-related hazards. Therefore OSHA provides a series of guidelines, manuals and as well a Heat Illness Prevention campaign, that gives employers and employees a great opportunity to be educated on the hazards of working in hot environments.

Let’s briefly discuss the causes that can lead to a heat stress, different symptoms of heat illnesses and how to prevent heat stress:

CAUSES:

Most of the following causes are related to outdoor working environments but indoor activities (e.g. iron and steel foundries, glass products facilities, electrical utilities/boiler rooms, bakeries, commercial kitchens, laundries, etc…) can also have a potential for causing heat-related illness.

- High temperature and high relative humidity

- Low fluid consumption

- Direct sun exposure or extreme heat

- Physical efforts

- Use of specific PPE (Personal Protective Equipment)

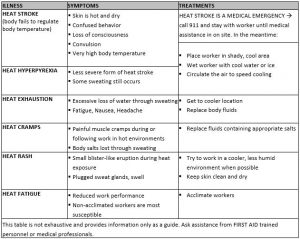

HEAT ILLNESSES, SYMPTOMS and FIRST AID/TREATMENTS:

(from most severe to less severe)

PREVENTION:

OSHA briefly and effectively summarizes what actions should be taken in order to prevent heat illnesses, in three words, that actually represents OSHA Heat Illness Prevention campaign: water, rest, shade. That gives a general but powerful idea of what employers and employees must take into account when they are engaged in working in hot (outdoor as well as indoor) environments.

Heat Illness Prevention can include:

- Engineering controls: the main idea of using EC (mostly for indoors workplace) is to cool down the working environment (i.e. air conditioning, cooling fans, increase general and local ventilation, etc.…)

- Work practices: like emergency plan, acclimatization (gradually build up exposure to heat), gradually increase of workloads, allow more frequent breaks, adequate potable water, rotation of jobs/tasks.

- Training: workers should receive appropriate training about the hazards of heat exposure, heat illnesses and their symptoms and prevention.

- PPE: special cooling devices can protect workers in hot environments (insulated gloves, insulated suits, reflective clothing, thermally conditioned clothing, etc..

Ultimately OSHA provides some general recommendations:

- It’s better to drink small amounts frequently, as opposed to larger amounts less often.

- Drink even if you don’t feel thirsty.

- When you’re not at work, still drink plenty of water to help your body recover from the workday.

- During a heat wave, it is recommended to provide more frequent breaks.

- Use the buddy system. Pair off and watch your co-worker for signs of heat exhaustion.

- Wear light-colored lightweight cotton clothing.

To learn more about the heat illness prevention, training or any other requirements set by the OSHA for heat stress for Construction (29 CFR 1926) or General Industry (29 CFR 1910) please contact Walden Environmental Engineering for a free consultation to discuss any issue about OSHA heat stress related compliance or about any of the other EHS engineering services we provide.