All About National Preparedness Month

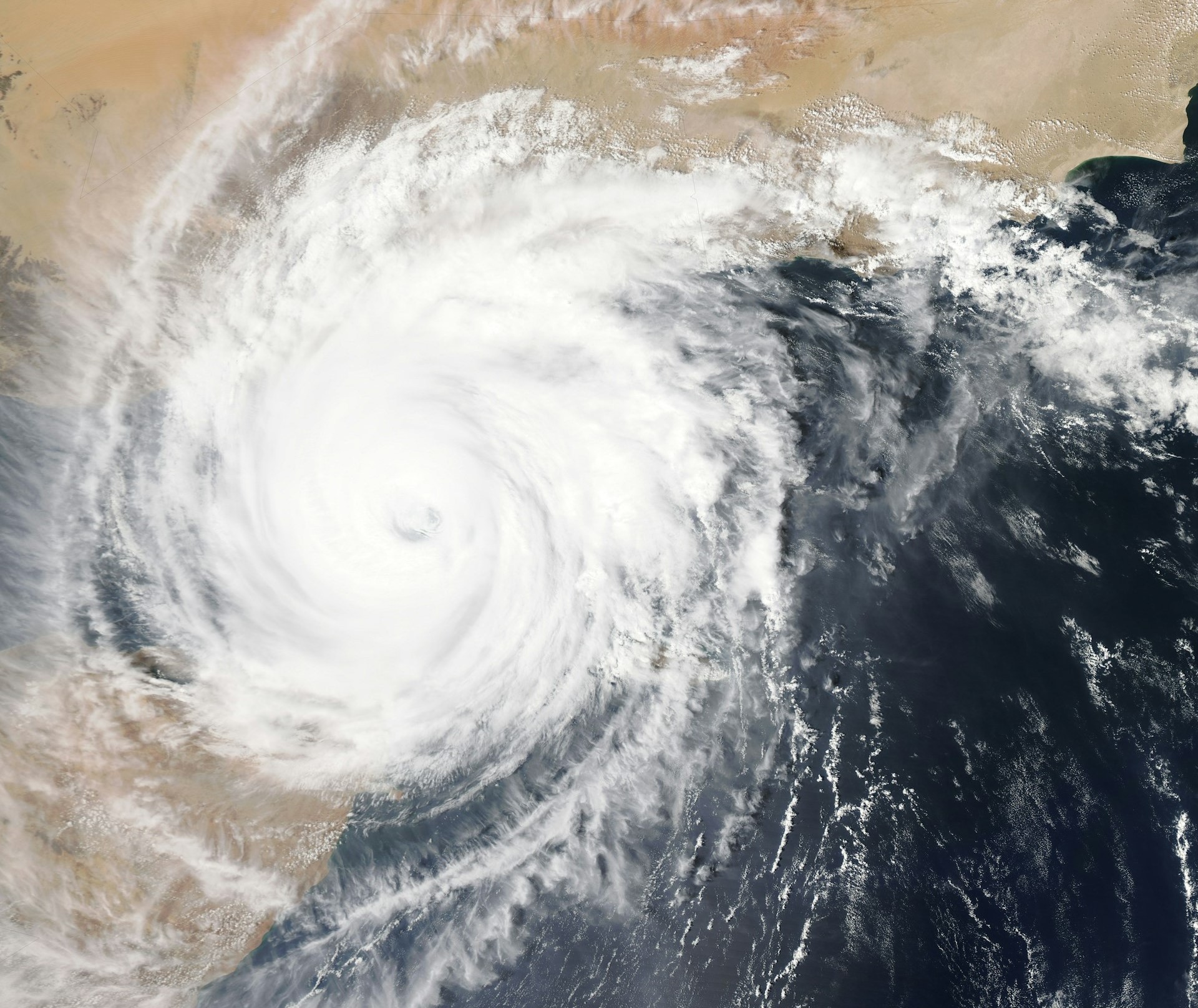

Whether talking about homes or businesses, there is a risk of disasters in our life every day. Natural disasters such earthquakes, hurricanes, tornadoes, floods, and wildfires have affected almost every region in the United States over the past few years. In addition, we must be prepared for several other kinds of emergencies, including structure fires, significant injuries, health emergencies, active shooters, train derailments, highway accidents, and more.

For manufacturers, preparedness is more than just best practices.

Did you know that OSHA has requirements for emergency preparedness?

Under OSHA Standard 29 CFR 1910.38, most workplaces are required to maintain a written Emergency Action Plan (EAP). This plan MUST include:

- Evacuation procedures and assigned exit routes

- Procedures for employees who remain to perform critical operations before evacuation

- Annual drills for every shift

- Employee trainings, including CPR/first aid trainings

- Reporting methods for emergencies (such as radios, fire alarms, and announcement systems)

- Contact information for key responders, emergency coordinators and backups, and even neighboring businesses

OSHA also requires training for anyone who would be asked to use a fire extinguisher or otherwise fight a fire.

What does a strong emergency plan involve?

What does a strong emergency plan involve?

When you run an emergency drill, you should make sure you have identified emergency coordinators, as well as backup coordinators, whose role is to account for the team. Each employee, contractor, and visitor should know where to go and who to report to in order to be accounted for in an emergency.

In addition to evacuation procedures, your plan should include shelter scenarios. Even if you don’t feel that a tornado is likely, knowing what to do in advance of one will be vital for the survival of everyone at the facility. This kind of planning is also necessary so that you know what to do if you receive an order to shelter in place due to a chemical spill or fire at neighboring businesses, on rail or highway corridors, or as part of any other unexpected event.

In the case of an industrial accident or medical emergency, does your team have people trained in CPR and first aid? If 911 is called, will someone go to the gate or driveway to meet the emergency vehicles and show them to the correct location? Do you have the right kind of first aid supplies on site to address a worst-case scenario injury?

By regularly reviewing and updating your emergency plans, you are ensuring that current risks and operations are continually being accounted for. Frequent trainings and drills are important opportunities to ensure employees actually know where to go, how to respond, and who to notify. Make sure your emergency supplies are always fully stocked and up to date, spill kits are ready, and flashlights and communication tools are plentiful and easily accessible.

Also, consider new hires, older employees, temporary staff, and employees with disabilities – these people can be the most vulnerable. Ensure that your plans and drills account for their safety.

How can Walden help?

How can Walden help?

Preparedness saves lives, reduces risk, and protects your employees, business, and community. If you need help developing an Emergency Action Plan, completing facility mapping, conducting fire extinguisher training, or running drills, please reach out to Walden. Our EHS professionals can help to ensure that your programs and practices are ready when an emergency strikes.

Contact us at 860-846-4069 to discuss your needs with a qualified safety specialist.

Photo credits:

Hurricane photo by NASA on Unsplash

CPR photo by Martin Splitt on Unsplash

Fire alarm photo by Jalen Hueser on Unsplash

What does a strong emergency plan involve?

What does a strong emergency plan involve? How can Walden help?

How can Walden help?